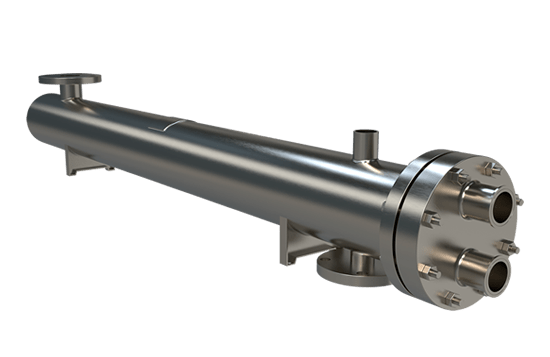

Sanitary

Heat Exchangers

Heat exchangers play a critical role in sanitary applications within the food and beverage industry, and other sectors where the product is intended for human or animal consumption. These sanitary exchangers are engineered to meet rigorous hygiene standards, ensuring products such as dairy, honey, juices, and liquid eggs are processed safely and efficiently.

Their design facilitates easy cleaning and sterilization, optimizing Clean In Place (CIP) processes and safeguarding against contamination. Used in pasteurization, they gently heat beverages and foods to eliminate pathogens without compromising quality. Heat exchangers also contribute to energy efficiency by recovering waste heat from hot fluids—affirming their necessity in sustainable manufacturing practices.

Sanitary Heat Exchangers

- Hygienic Design: Ensures safety and compliance with stringent industry health standards.

- Enhanced Product Quality: High quality materials and close temperature control maintain taste and nutritional value during temperature processing.

- Versatility: Suitable for a broad range of applications such as dairy and beverage pasteurization, medical fluid preparation, and clean in place (CIP) applications.

- Advanced Temperature Control: Provides precise heating for delicate products like honey and pulpy juices.

MARKETS

Engine Cooling

Hydraulic Cooling

Process Cooling

Compressor Aftercoolers

Condensers

Irrigation Coolers

Injection Molding