Gasketed Plate & Frame

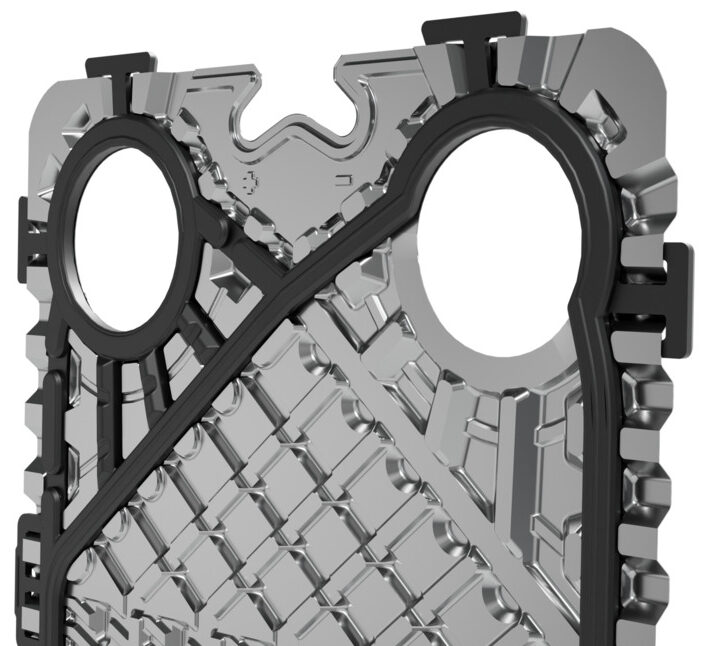

Engineered for maximum uptime and adaptability, gasketed plate and frame units combine robust pressure frames with precision-stamped plates and field-replaceable sealing gaskets to achieve exceptional thermal performance, rapid maintenance turnaround, and seamless integration across sanitary, industrial, and utility applications.

- Flexible Configurations: Single-pass, multi-pass, semi-welded, wide-gap, and free-flow models tailored to fluid characteristics.

- Scalable Performance: Wide range of surface areas servicing micro to mega-scale operations.

- Premium Alloys: 304L, 316L, Titanium Gr.2, Alloy 254, Hastelloy C-276, and Incoloy for extreme compatibility.

- Enhanced Flow Dynamics: Proprietary chevron angles, inlet zones, and turbulence promoters reduce fouling and boost U-values.

- Code-Certified Builds ASME Section VIII, PED 2014/68/EU, FDA, 3-A, and CRN registered designs.

- Specialized Sealing EPDM, NBR, Viton, PTFE-coated, or clip-on gaskets for temperature, chemical, and hygiene demands.

Complete Units

Industrial & Sanitary

- High-Volume Flow Capacity

- Corrosion-Resistant Stainless

- Easy Field Expansion

Plates & Gaskets

OEM Replacements

- 304, 316 & Titanium

- NBR, FDA, EPDM & More

- Stock and Short Leadtime

Gasketed Plate & Frame Systems

Core Applications

Deployed worldwide in ultra-high-efficiency processes including HTST pasteurization, clean-in-place preheat, district energy networks, glycol loop cooling, bio-pharmaceutical WFI heating, viscous slurry cooling, refinery interchangers, data center liquid cooling, and geothermal energy extraction.

Engineering Specifications

Frames constructed to ASME U-stamp or PED Module H, with plate embossing depths from 2.5 mm to 6 mm and port diameters up to 20 inches. Maximum design pressure 362 psi (25 bar), temperature range -60°F to 400°F. Heat transfer coefficients routinely exceed 1,500 BTU/hr·ft²·°F. Configurations support true counter-current flow with temperature crosses up to 1:1.2 ratio.

Complete compliance portfolio includes USDA, PMI, seismic UBC Zone 4, and marine ABS/DNV type approval. Optional features: insulated shrouds, backflush connections, drip pans, and PLC-integrated leak detection.

Standard Gasketed Units

Traditional clip- or glue-free gasket systems allow plate pack removal in under 30 minutes. Field-addable plates increase capacity by 100% without new frame purchase. Ideal for utilities, HVAC, and general process fluids with moderate fouling potential.

Semi-Welded Cassettes

Laser-welded twin-plate cassettes contain aggressive refrigerants or corrosives on one circuit while retaining full gasket serviceability on the opposite side. Eliminates O-ring failures in ammonia evaporators and caustic soda concentrators.