Gas Cooling and Condensing for Industrial Efficiency

Gas cooling and condensing processes are critical for managing gases such as landfill gas, bio gas, ethanol gas, argon gas, nitrogen gas, helium gas, carbon dioxide gas, and hydrogen gas in industries like renewable energy, chemical processing, and environmental management. Shell and tube heat exchangers facilitate precise cooling and condensation by transferring heat from hot gas streams to a cooling medium, enabling efficient temperature control and phase transition. These systems ensure process stability, equipment protection, and compliance with environmental and safety standards, handling high-pressure and corrosive conditions while maintaining gas purity.

Applications

- Energy Recovery: Shell and tube heat exchangers cool and condense landfill and bio gas, optimizing methane recovery for power generation while reducing emissions.

- Chemical Processing: Cooling and condensing ethanol, nitrogen, and hydrogen gases ensures safe and efficient reactions in chemical synthesis and biofuel production.

- Cryogenic and High-Purity Applications: Precise cooling of helium, argon, and carbon dioxide gases supports cryogenic systems and semiconductor manufacturing, maintaining purity and performance.

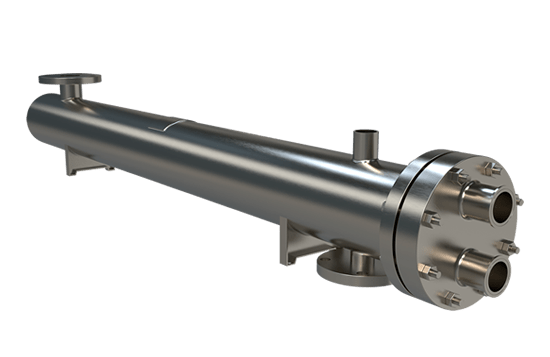

Shell and Tube Heat Exchangers

Gas Cooling

- Robust Design for High Pressures

- Corrosion-Resistant Materials

- Suitable for Large Gas Volumes

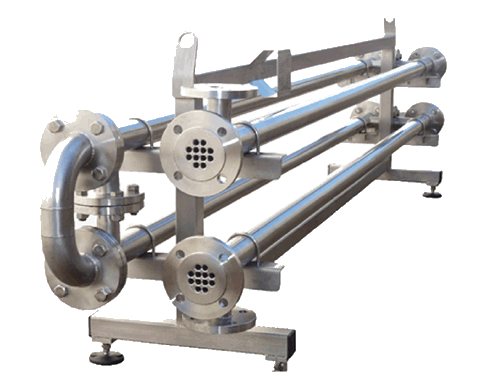

Custom Heat Exchangers

Gas Condensing

- Customizable for Specific Gases

- High Thermal Efficiency

- Easy Maintenance Design

Gas cooling and condensing is vital for processing gases like landfill gas, bio gas, ethanol gas, argon gas, nitrogen gas, helium gas, carbon dioxide gas, and hydrogen gas across diverse industries. In renewable energy, shell and tube heat exchangers cool and condense landfill and bio gas to optimize methane recovery for power generation, reducing greenhouse emissions. In chemical processing, cooling and condensing ethanol and hydrogen gases ensures safe conditions for biofuel production and ammonia synthesis. For high-purity applications, helium and argon gas cooling supports semiconductor manufacturing and cryogenic systems, maintaining strict purity standards. Carbon dioxide gas cooling aids in refrigeration and dry ice production, while nitrogen cooling enhances food preservation and pharmaceutical processes. These systems, built with corrosion-resistant materials, handle high-pressure conditions and comply with environmental regulations, ensuring reliability and efficiency.

The efficiency of gas cooling and condensing relies on precise thermal management and robust equipment design. Shell and tube heat exchangers provide high heat transfer rates, enabling rapid cooling and condensation of gases to prevent equipment damage and ensure process stability. Their customizable configurations accommodate the unique properties of each gas, from the high flammability of hydrogen to the low boiling point of helium. Automated clean-in-place (CIP) systems reduce maintenance downtime, ensuring continuous operation in high-throughput facilities. By optimizing energy recovery and minimizing emissions, these heat exchangers support sustainable operations, reduce operational costs, and enable compliance with stringent environmental and safety standards.

Beyond efficiency, gas cooling and condensing systems enhance operational flexibility. The ability to process multiple gas types—such as landfill gas for energy, argon for welding, or carbon dioxide for refrigeration—makes shell and tube heat exchangers versatile for industries like energy, chemical, and food processing. Their durable construction withstands aggressive cleaning regimes and high-pressure environments, ensuring long-term reliability. By enabling precise phase transitions and temperature control, these systems support global distribution of high-quality products, from biofuels to medical-grade gases, while minimizing environmental impact through reduced energy consumption.