Compressor Cooling Solutions

Compressor cooling systems, such as aftercoolers, are designed to cool compressed air, condense moisture, and protect downstream equipment in industrial applications. These systems ensure dry, cool air for processes like pneumatic tool operation, spray painting, and abrasive blasting, enhancing efficiency and equipment longevity.

Air-Cooled Aftercoolers:

Industrial Applications

- Cost-Effective Cooling

- Integrated Moisture Separator

- Low Pressure Drop Design

Water-Cooled Aftercoolers:

Industrial Applications

- High-Efficiency Cooling

- Removable Tube Bundles

- High-Pressure Capability

Industrial Compressor Cooling Systems

Air-Cooled Aftercoolers for Compressor Cooling

Air-cooled aftercoolers are widely used in compressor cooling to reduce the temperature of compressed air, enabling moisture removal and preventing corrosion in downstream equipment. These aftercoolers use ambient air for cooling, making them a cost-effective solution for applications like sandblasting and pneumatic tools. Models are available in various sizes, with features like fan-assisted cooling, integrated moisture separators, and corrosion-resistant materials such as aluminum or stainless steel, ensuring durability and compliance with ASME standards.

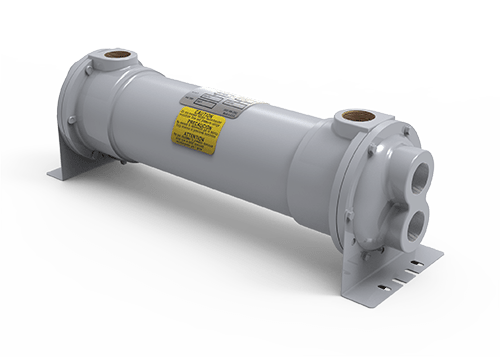

Water-Cooled Aftercoolers for Compressor Cooling

Water-cooled aftercoolers provide superior cooling efficiency for high-volume or high-temperature compressor systems. Using water as a cooling medium, they are ideal for industries like chemical processing and heavy manufacturing. Constructed with stainless steel, these aftercoolers feature removable tube bundles for easy maintenance, high-pressure capabilities, and options for anti-fouling coatings, ensuring long-term reliability and performance.

Benefits of Compressor Cooling

Compressor cooling systems enhance operational efficiency by removing moisture, reducing energy costs, and protecting equipment from corrosion. They are customizable for various flow rates and pressures, environmentally friendly with low energy consumption, and require minimal maintenance. Additional benefits include improved air quality, reduced downtime, and high durability in harsh industrial conditions.

Applications of Compressor Cooling

Compressor cooling is essential in industries such as manufacturing, automotive, and construction. Applications include cooling air for abrasive blasting, spray painting, pneumatic machinery, and high-pressure air systems, ensuring consistent performance and product quality.