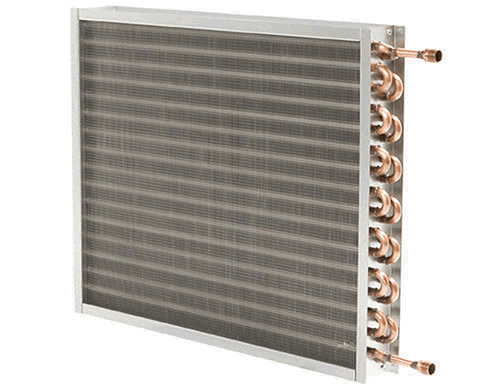

Finned Coil

Finned coil heat exchangers are built with extended surface area for superior air-side heat transfer. Custom fin spacing, tube materials, and configurations support high thermal performance, while optional coatings, drain pans, and corrosion-resistant materials ensure longevity, efficiency, and ease of service in demanding environments.

Engineered to provide excellent heat transfer for a variety of applications, our finned coils are a staple in industries that demand precise air temperature control and reliability. Whether you're working in HVAC, process cooling, refrigeration, or industrial drying, our coils are designed to withstand the test of time.

Crafted with high-quality materials and precision, our finned coil heat exchangers offer exceptional durability. The robust construction ensures optimal performance even under extreme conditions, making them the go-to solution for your air-to-fluid needs. Their versatility is unmatched, as they can accommodate both high and low-flow applications with ease.

Our commitment to excellence guarantees that our clients receive heat exchangers that not only meet but exceed industry standards. Keep your operations running smoothly with the consistency and thermal control that your business depends on. Explore our solutions today and see the difference that potent and professional heat exchange equipment can make to your bottom line.

- Multiple Designs: 1 to 12 row deep, multi-pass, staggered/inline tube arrangements for optimal heat transfer.

- Available Capacities: From 1 sq ft to 1,000+ sq ft of face area, handling small to massive thermal loads.

- High Quality: Copper, aluminum, stainless steel, CuNi fins/tubes for durability and fluid compatibility.

- Efficiency: High fin density, turbulence-inducing fins, and optimized circuitry maximize heat transfer and minimize pressure drop.

- Custom Fabrication Any fin type, spacing, tube diameter, or circuiting with full compliance.

- Materials Corrosion-resistant coatings and alloys for humid, marine, chemical, or high-temperature air.

Industrial:

Heavy-Duty & Process

- Custom Fin Spacing

- High Temps & Pressures

- Custom Materials & Sizes

HVAC:

Heating, Cooling & Ventilation

- High Efficiency Fins

- Coated & Galvanized Options

- Easy Clean Design

Finned Coil Exchangers

Applications

The following is a list of typical processes that require finned coil heat exchangers: air cooling/heating, process air tempering, refrigeration, HVAC systems, compressor aftercooling, dryer air heating, gas cooling, waste heat recovery, and thermal management in industrial and commercial settings.

Sizes & Materials

Finned coil units feature copper or stainless tubes, aluminum/copper/stainless fins, with fin spacing from 6 to 14 FPI. Tube diameters from 1/4" to 1", row depths up to 12+, and face areas exceeding 100 sq ft support high air volumes and temperatures up to 400F+. Coatings, headers, and casings optimize flow, durability, and corrosion resistance.

Available in multi-pass, interlaced, or face-split circuits, with compliance to AHRI, ASME, and industry standards. Custom fin types (plate, spiral, extruded), casing materials, and drain/vent options ensure seamless integration and long-term performance in humid, corrosive, or fouling environments.

Standard Fin Coils

Standard fin designs offer high efficiency and low air-side pressure drop. Available in various row depths and fin spacings, they support clean air applications or where frequent cleaning is required.

Enhanced Fin Coils

Enhanced fin exchangers provide higher heat transfer in compact footprints. They excel in high delta T applications, dirty air streams, and environments requiring maximum thermal performance.